Overview

Development Process

You complete our ARE Technical Data Sheet (TDS) with what is going on your pole and where.

Next, we’ll run a Preliminary Analysis (PA) using your specific site details – elevation, exposure, wind, ice loading – to TIA Code to determine your poles Base Moment. With this value, we select the foundation size.

Your Structural Certification (SA) will be produced with a wet-stamp for your state and either incorporate your Soil PSF, or state the minimum Soil Bearing Capacity.

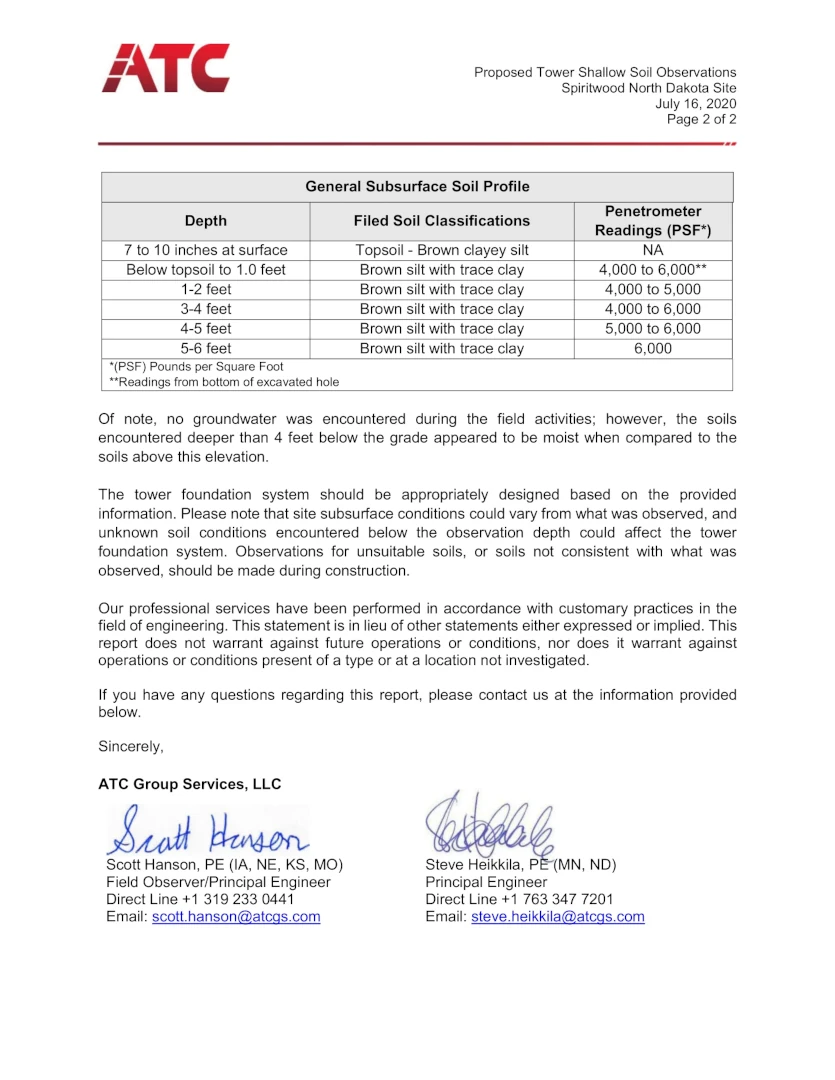

A Geotechnical Report stating the Soil Bearing Capacity is all that is needed for an ARE Ballasted Foundation, typically a much faster and less costly test than conventional Core Sample Geo’s.

Engineering Process

At ARE, we understand the importance of engineering in delivering quality and reliable infrastructure solutions. While we have one in-house engineer, we also partner with Paul J. Ford to bring additional engineering expertise to our clients. Our team of experienced engineers works closely together to deliver high-quality, cost-effective solutions that meet or exceed industry standards.

Our engineering services focus on delivering reliable, safe, and efficient structures through thorough analysis and testing, such as soil bearing tests. We tailor solutions to meet specific project requirements, utilizing our in-house expertise and commitment to innovation and leadership demonstrated by our patents.

Customization

ARE provides personalized tower engineering services and comprehensive foundation engineering services to address the distinct requirements of every infrastructure project. Our adaptable and flexible solutions are customized to meet specific needs, including self-raising poles and specialized testing. By collaborating closely with our clients, we gain a deep understanding of their needs and develop tailored solutions that precisely meet their requirements. Our unwavering emphasis on quality, reliability, and efficiency guarantees that our customized solutions deliver exceptional results.

Custom Engineering

We are dedicated to providing pole engineering services customized to your specific requirements. This includes incorporating features such as hand-holes, brackets, doors, and interior ladders as needed. Additionally, if further modifications are necessary, we can adapt our existing foundations or create new ones to precisely align with the needs of your project.

Almost all of our foundations and products started with a customer need that we set-out to meet. In fact, our first ballasted foundation was for the US Army who contacted ARE to combine our self-raising 30’ pole with a quick-to-deploy and rugged foundation. Since then, we’ve deployed more than 1,000 AFS 150-200 systems from the Arctic to the US southern border, Tasmania, Europe and more.

Geotechnical

Our AFS Ballasted Foundations offer a more efficient alternative to traditional concrete foundations. Instead of requiring a time-consuming and costly core sample, we only need the Soil Bearing Capacity for Structural Certifications. The method employed to determine the soil bearing may vary depending on the site, typically involving hand tools, small motorized probes, or visual inspection conducted by a licensed Geotech Engineer.

At ARE, we collaborate with you and your local Geotech Firm to ensure we obtain the necessary information while minimizing the need for core samples whenever possible. Alternatively, if you prefer, we can handle the Geotech Report on your behalf through our national partner, who has offices across the country. This approach expedites the process, leverages our volume, and guarantees a comprehensive report with all the required information for your specific Structural Analysis (SA).

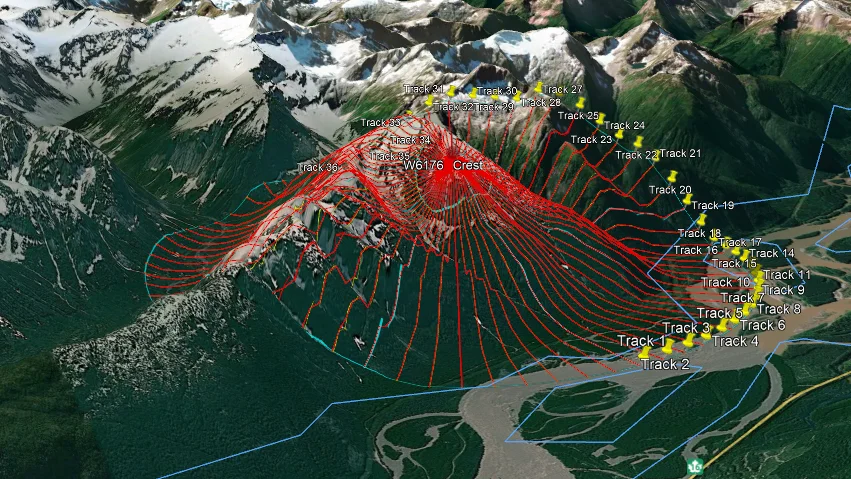

Retaining Walls

One advantage of our systems is their suitability for assembly in remote areas, even on uneven terrain. When installing our systems on hillsides or slopes, a flat area is necessary. Factors such as soil bearing capacity and water run-off must be considered. In most cases, a retaining wall is the solution, which can be built using conventional small locking blocks or pre-cast concrete blocks.

For sites with a slope of 1' or 2', a Class 5 material can be compacted with anti-erosion fabric and 6"+ rocks to support the built-up Class 5. Up to a height of 3', boulders measuring 12"-18" can be positioned to provide stability and support for the compacted fill, or locking landscaping blocks can be used. For heights between 4' and 6', pre-cast blocks are employed.

While each installation site has its unique characteristics that require careful consideration, our stock drawings serve as a foundation for understanding when and how walls are constructed to create the flat surface necessary for an ARE Ballasted Foundation.

Pre-Cast Ballast Blocks

ARE's patented Ballasted systems offer flexible options for ballast materials, in addition to using local sand, gravel, or aggregate.

Unlike other ballasted platforms that rely on custom-engineered blocks, which can be heavy and expensive to ship, ARE's ballasted requirements are adaptable to various materials, as long as the necessary ballast weight is achieved. This allows us to utilize cost-effective and practical options such as pavers, bricks, or precast blocks, based on the specific needs of your project and installation.